Products

WHAT IS MIG-TC?

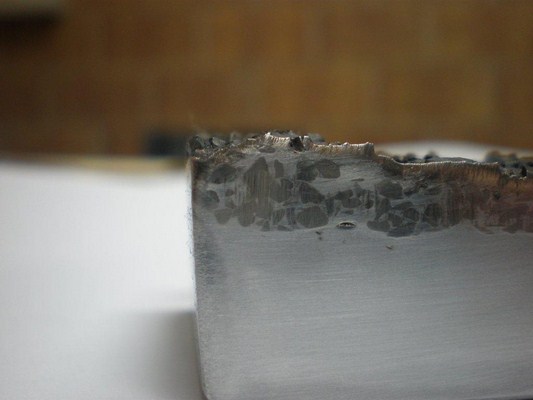

MIG Tungsten Carbide utilizes the MIG welding process along with a special hardfacing wire and Tungsten Carbide particles to form a composite hardfacing that is highly resistant to severe abrasion and impact. It is made from extremely hard tungsten carbide particles (70Rc), deposited in a specially designed tool steel weld matrix – Hardfacing Wire at 58 Rc.

The tungsten carbide particles are held in a hopper located directly above the welding operation. Immediately upon beginning to weld, the TC particles are dropped through a tube that is attached to the MIG gun nozzle and then feed directly into the molten Hardfacing wire matrix weld.

MIG-TC offers a tremendous increase in service life compared to parts that do not have it.

HOW TO GO ABOUT IT?

To decrease the material lost from the wear prone parts, the critical areas should be hardfaced with MIG Carbide according to the material that the wear prone part will be working with.

The material used as hardfacing – Tungsten Carbide with the specially formulated hardfacing wire - will have hardness greater than the material causing the wear. This significantly decreases the loss of material from abrasive wear.

FREQUENTLY ASKED QUESTIONS

Q. Does the MIG-TC hardfacing application change the properties of the base metal? Will it be softer? When the tungsten carbide/Hardfacing Wire wears away, will the base metal parts wear more quickly?

A. That is what many of our competitors would like to believe. However, several metallurgical analyses have been conducted. They show that the heat affected area (HAZ) is around 1mm right below the hardfacing's matrix. The HAZ has the same hardness as the base metal.

Q. What is the longest service life that products coated with MIG-TC have attained?

A. This is a hard question to answer because there so many variables, especially in hardfacing cutting edges, blades and parts exposed to wear from abrasion, impact, erosion, etc. Generally, an increase in wear life of 6 to 10 times can be expected for parts that are not hardfaced. Wear parts that are currently being hardfaced can expect a 3 to 6 times improvement in wear life.